What are the uses of chemical pumps

Chemical pumps are energy-saving pumps that are jointly designed throughout the country. The performance and technical requirements of the pumps are designed according to the performance and size specified in the international standard ISO2858.

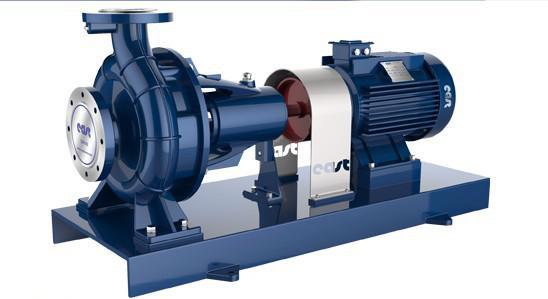

Chemical pumps are energy-saving pumps that are jointly designed throughout the country. The performance and technical requirements of the pumps are designed according to the performance and size specified in the international standard ISO2858. They can be divided into stainless steel chemical pumps and plastic chemical pumps, fluoroplastic chemical pump, electric chemical pump, pneumatic chemical pump. The advantages of chemical pumps are reasonable layout of water conservancy performance, wide selection range of users, "open-back" structure, easy maintenance, efficiency and suction reach the international advanced level. Depending on the purpose of the chemical pump, process pump: including feed pump, reflux pump, circulation pump, flushing pump, sewage pump, Supplement pump, output pump, etc. . 2) public works pumps: including boiler pumps, cooling tower pumps, fire pumps, deep well pumps for water sources, etc. . 3) AUXILIARY PUMPS: including lubricating oil pump, sealing oil pump, hydraulic transmission pump, etc. . 4) PIPELINE PUMPS: PUMPS FOR OIL PIPELINES, loading and unloading trucks, etc.